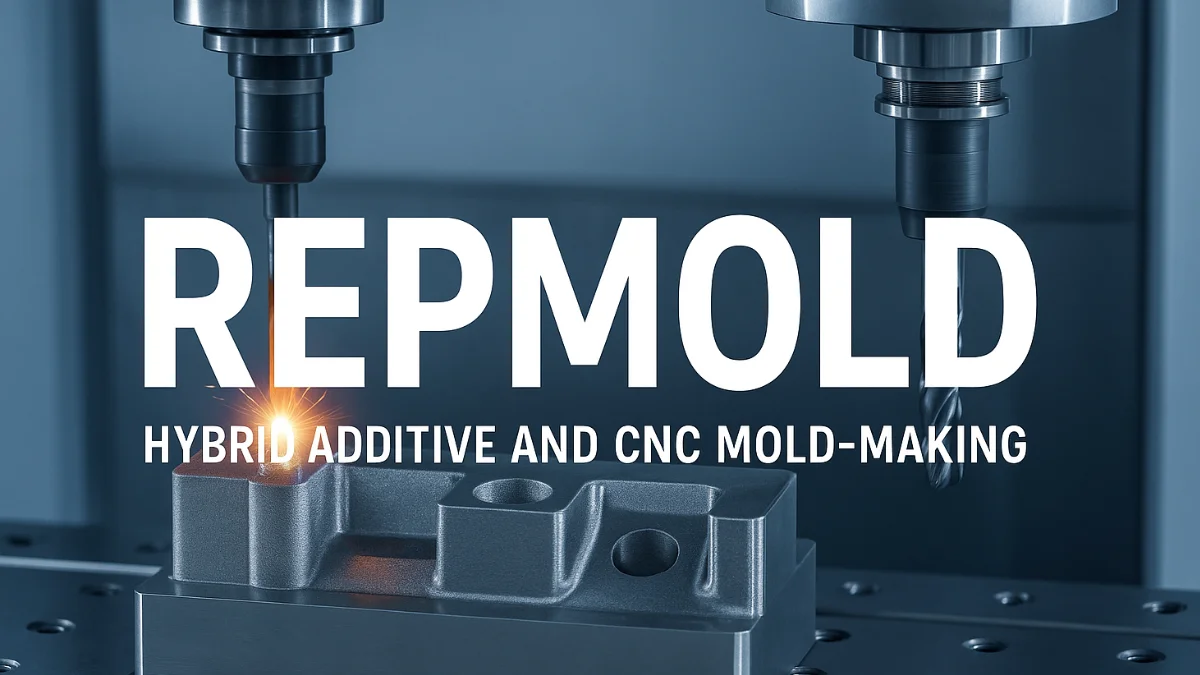

Let’s be honest—for decades, the world of mold-making could feel a bit like watching paint dry. It was a necessary but slow, expensive, and rigid process, often acting as a bottleneck for innovation. If you wanted to design a new component, you’d face weeks, if not months, of lead time and hefty costs before you even had a prototype mold. That era is decisively ending. Enter Repmold, a revolutionary approach to mold creation that is tearing up the old rulebook.

By synergizing cutting-edge technologies like additive manufacturing and high-precision CNC machining, Repmold isn’t just an incremental improvement; it’s a paradigm shift towards unprecedented speed, breathtaking precision, and remarkable flexibility in manufacturing.

At its core, Repmold represents a fundamental rethinking of how we go from a digital design to a physical production tool. It moves away from purely subtractive, time-intensive methods and embraces a hybrid, agile methodology. This isn’t about replacing one machine with another; it’s about integrating a smarter workflow that allows manufacturers to iterate faster, waste less, and confidently tackle designs that were once deemed too complex or costly to produce. For industries where the margin for error is zero—think aerospace, automotive, and medical devices—this isn’t just convenient; it’s transformative.

From Chisel to Chip: The Evolution of Mold-Making

To truly appreciate the leap that Repmold represents, it helps to glance back. Mold-making is one of humanity’s oldest crafts, evolving from artisans carving forms in stone or clay for casting metals. The Industrial Revolution introduced pattern-making and more standardized tooling, but the process remained manual and slow.

The first seismic shift came with the advent of Computer Numerical Control (CNC) machining in the mid-20th century. Suddenly, molds could be milled from blocks of metal with digital precision, dramatically improving accuracy and repeatability. Yet, CNC is inherently subtractive—you start with a solid block and remove material, which can be time-consuming and wasteful for complex internal geometries.

The next breakthrough, additive manufacturing (3D printing), flipped the script entirely in the 1980s and 90s. It allowed for the creation of shapes by adding material layer by layer, directly from a CAD file. While revolutionary for prototypes, early 3D-printed molds often lacked the durability, surface finish, and thermal properties needed for full-scale production.

Repmold emerges as the intelligent synthesis of these technologies. It asks: why choose one? By using 3D printing to rapidly create mold cores and cavities with conformal cooling channels—something impossible with traditional CNC—and then employing CNC machining for critical sealing surfaces and fine details, we get the best of both worlds. This hybrid approach is the heartbeat of the Repmold methodology.

The Technological Engine Room: What Powers Repmold?

So, what’s under the hood of this advanced mold-making approach? Repmold isn’t powered by a single magic bullet but by a suite of interoperating technologies.

-

Advanced Additive Manufacturing: This is the cornerstone for speed and complexity. Technologies like Direct Metal Laser Sintering (DMLS) or Binder Jetting are used to print mold inserts from tool steel or maraging steel. The real superpower here is the ability to create conformal cooling channels. These channels follow the contour of the mold cavity, allowing for vastly more efficient cooling, which reduces cycle times by up to 70% and minimizes part warpage.

-

High-Precision CNC Machining: Repmold utilizes CNC for what it does best: achieving flawless surface finishes, tight tolerances on sealing planes, and critical part-line edges. The hybrid model means CNC work is focused and efficient, no longer wasting time on deep, complex cavities.

-

Digital Twin & Simulation Software: No metal is committed until the entire molding operation has been modeled and tested digitally. Software predicts flow, cooling, and stress, allowing engineers to optimize the mold design digitally. This virtual prototyping identifies potential defects like air traps or sink marks, slashing the costly trial-and-error phase. A study by ANSYS highlights how simulation can reduce physical prototyping cycles by over 50% in complex tooling projects.

-

Innovative Materials: The ecosystem includes not just advanced metal powders for printing but also high-performance sintered alloys and composite materials that offer unique blends of thermal conductivity, hardness, and wear resistance tailored for specific production runs.

Repmold vs. Traditional Mold-Making: A Side-by-Side Look

The following table illustrates the fundamental shifts brought by the Repmold approach:

| Feature | Traditional Mold-Making | Repmold Approach |

|---|---|---|

| Lead Time | 8-16 weeks (or more) | 2-5 weeks |

| Design Complexity | Limited by machining tool access | Extremely high; enables organic geometries & conformal cooling |

| Prototyping & Iteration | Slow and prohibitively expensive for mold changes | Fast and cost-effective; digital twins & additive inserts |

| Material Waste | High (subtractive process) | Significantly reduced (near-net-shape additive) |

| Cooling Efficiency | Standard drilled channels, less efficient | Optimized conformal channels, much faster cycle times |

| Upfront Cost | Lower for simple molds, scales steeply with complexity | Higher initial tech investment, but more predictable and efficient |

| Best For | High-volume, simple geometry, stable designs | Low-to-medium volume, complex parts, rapid innovation cycles |

Where Repmold Takes Flight: Real-World Applications

Repmold’s versatility is now demonstrated globally in both operational factories and research laboratories.

-

Automotive & Aerospace: These sectors crave lightweight, strong components. Repmold allows for the production of molds for complex intake manifolds, lightweight structural brackets, and ducting with integrated features. The rapid iteration is crucial for prototyping new engine components or drone parts, getting them to testing phases in a fraction of the time.

-

Consumer Electronics: The race to make devices thinner, lighter, and more ergonomic demands intricate mold geometries. Repmold excels at creating molds for complex smartphone housings, wearable device components, and heat sinks with fine-pitch fins, all while maintaining the exquisite surface finish the market expects.

-

Medical & Dental: Here, customization is king. Repmold is ideal for producing molds for custom surgical guides, dental aligners, and specialized prosthetic components. The ability to quickly and cost-effectively produce small batches of highly precise, patient-specific tooling is a game-changer for personalized medicine.

-

Consumer Goods: From ergonomic tool grips to complex packaging with unique textures, Repmold enables designers to experiment with forms that were previously too costly to mold, fostering greater product differentiation.

Weighing the Balance: Advantages and Considerations

The benefits of adopting a Repmold framework are compelling:

-

Unmatched Speed: The dramatic compression of the design-to-tool timeline is perhaps its biggest draw, enabling faster time-to-market.

-

Complexity for Free: Engineers are liberated from many traditional design-for-manufacturability constraints, unlocking innovation.

-

Superior Part Quality: Conformal cooling leads to more uniform part crystallization, less stress, and fewer defects.

-

Cost-Effectiveness for Complexity: For complex, low-to-medium volume production, Repmold often has a lower total cost than traditional tooling.

-

Sustainability: Significant reductions in material waste (subtractive vs. additive) and energy use from shorter cycle times contribute to a greener manufacturing footprint.

Of course, no technology is a universal panacea. Considerations include:

-

Initial Investment: Implementing Repmold requires investment in new technology, software, and specialized expertise.

-

Material Portfolio: While growing rapidly, the range of qualified, printable tool steels is not yet as vast as traditional block materials.

-

Volume Thresholds: For extremely high-volume production runs (millions of cycles), traditional hardened steel molds may still have a longevity advantage, though Repmold inserts can often be replaced quickly.

The Road Ahead: The Future of Repmold

The trajectory for Repmold is pointed sharply upward. We are moving towards even more integrated digital threads, where the CAD model flows seamlessly through simulation, to the factory floor, and into quality assurance with AI-driven inspection. The integration of AI and machine learning will further optimize mold design parameters automatically, predicting lifespan and maintenance needs.

Furthermore, the development of new high-temperature alloys and ceramic composites for additive manufacturing will push Repmold into even more demanding production environments. As the technology matures and becomes more accessible, it will shift from a competitive advantage to a standard expectation for agile, innovative manufacturers.

FAQs

Conclusion: Is Your Manufacturing Strategy Ready?

Repmold is more than a new piece of equipment; it’s a testament to a smarter, more responsive, and more innovative way of building the things the world needs. It bridges the gap between the brilliant freedom of digital design and the practical realities of physical production.

For business leaders and engineers, the question is no longer if this technology will impact your field, but when. The early adopters in automotive, aerospace, and medical tech are already reaping the rewards in faster innovation cycles and superior products. Exploring how Repmold’s principles of speed, precision, and flexibility can be integrated into your production workflow isn’t just about keeping up—it’s about building a decisive advantage for the future.

The next step is to begin a concrete evaluation: analyze a current or upcoming project that faces traditional tooling challenges, and model how a Repmold methodology could transform its timeline, cost, and design potential. The mold for the future is being printed today.

Learn about GLDYQL

I’m Salman Khayam, founder and editor of this blog, with 10 years of experience in Travel, Lifestyle, and Culture. I share expert tips on Destinations, Hotels, Food, Fashion, Health, and more to help you explore and elevate your lifestyle.